To make a 36 volt battery charger, gather components such as transformers, rectifiers, and capacitors. Assemble the components based on the charger’s specifications and connect them using appropriate wiring techniques.

To ensure safety and efficiency, double check all connections and perform a thorough testing of the charger before use. Creating a 36 volt battery charger involves gathering necessary components such as transformers, rectifiers, and capacitors, then assembling and connecting them according to the charger’s specifications.

Proper wiring techniques are crucial, as is testing the charger thoroughly before use to ensure safety and efficiency. This introduction will discuss the essential steps and considerations required to successfully make a 36 volt battery charger, offering a comprehensive understanding of the process.

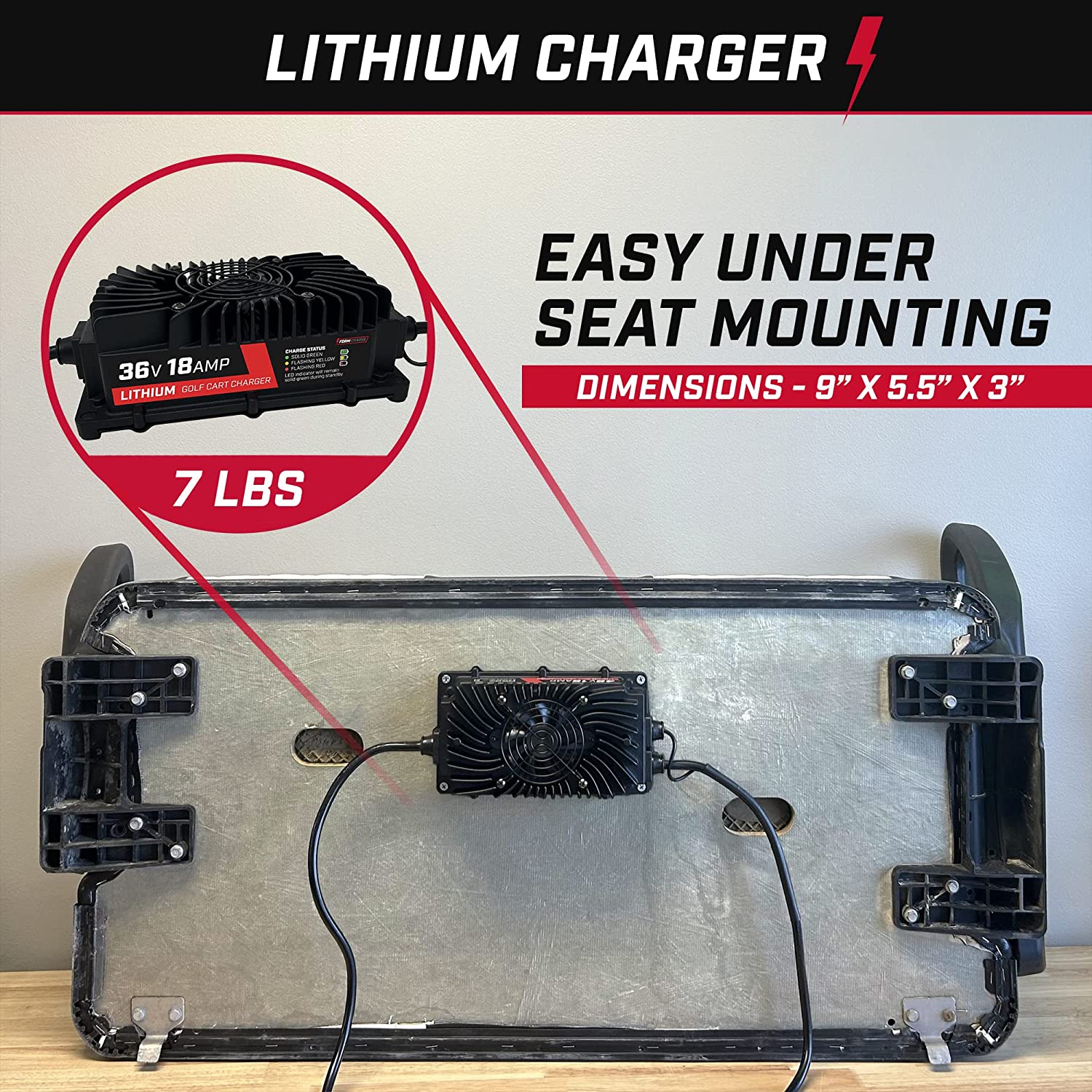

Credit: www.formcharge.com

Understanding 36 Volt Battery Chargers

Basics Of Battery Charging And Voltage Requirements

A 36-volt battery charger is an essential component for properly maintaining the voltage levels of 36-volt batteries, commonly used in golf carts, electric bicycles, and industrial equipment. Before diving into the specifics of building a 36-volt battery charger, it’s crucial to understand the basics of battery charging and the voltage requirements.

A battery charger works by replenishing the energy within a battery. When a battery is being charged, an electrical current is forced through the battery in the reverse direction to restore its energy. The voltage requirements for a 36-volt battery charger are critical, as the charger must match the voltage of the battery for effective and safe charging.

Key Components Of A 36v Battery Charger

When constructing a 36-volt battery charger, it’s essential to have a clear understanding of the key components necessary for the charger to function properly. These components include a transformer, rectifier, smoothing capacitor, control circuit, and voltage regulator.

The transformer is responsible for stepping down the voltage from the AC power source to the appropriate level for the battery. The rectifier converts the AC voltage to DC. The smoothing capacitor helps stabilize the DC voltage output, while the control circuit and voltage regulator ensure the charging process is controlled and the voltage levels are maintained within the safe operating range.

Safety Considerations When Building A Charger

When building a 36-volt battery charger, safety should be the top priority. It’s crucial to follow safety guidelines and precautions to avoid any potential hazards or accidents. Proper insulation of components, grounding of the circuit, and using appropriate safety equipment are essential. Additionally, understanding the voltage and current limits of the charger components is crucial in ensuring the safety and reliability of the charger.

Selecting Components For Your Charger

When it comes to making a 36 volt battery charger, selecting the right components is crucial to ensure the efficiency and safety of the charger. Each component plays a specific role in the charging process, and careful consideration is needed to ensure they work together effectively. In this section, we will discuss how to source the right power transformer, identify the correct rectifier and filter capacitor, and choose a suitable voltage regulator for your 36 volt battery charger.

Sourcing The Right Power Transformer

In order to build a 36 volt battery charger, the first critical component to select is the power transformer. Ensure that the transformer’s primary winding matches the available voltage supply, and the secondary winding provides the desired output, typically 36 volts. Consider the current requirements of the charger to select a transformer that can handle the necessary charging current. Look for a transformer with multiple output taps if you need the option to adjust the charging voltage.

Identifying The Correct Rectifier And Filter Capacitor

After selecting the power transformer, identify the correct rectifier and filter capacitor to convert the alternating current (AC) output of the transformer into direct current (DC). Choose a diode bridge rectifier capable of handling the expected charging current and voltage. Select a filter capacitor with appropriate capacitance and voltage ratings to smooth the rectified DC output and minimize ripple voltage.

Choosing A Suitable Voltage Regulator

To maintain a stable output voltage, ensure the selection of a suitable voltage regulator. Consider using a linear regulator for simplicity and effectiveness in maintaining a constant output voltage. Select a voltage regulator that can handle the input voltage range and current requirements, while providing a stable 36 volt output for the battery charging.

How To Make A 36 Volt Battery Charger

Building your own 36-volt battery charger can be a rewarding and cost-effective project for anyone keen on DIY electronics. Whether you need to power an electric bike, scooter, or other specialty vehicle, having the capability to create your own battery charger gives you greater control over the charging process. By following this step-by-step guide and preparing the necessary tools and materials, you can achieve a fully functional 36-volt battery charger tailored to your specific requirements.

Preparing The Necessary Tools And Materials

Before getting started, it’s essential to gather the following tools and materials:

- Soldering iron and solder

- Multimeter

- 36-volt transformer

- Bridge rectifier

- Capacitor

- Resistors and diodes

- DC jack

- Enclosure for the charger

- Wire, heat-shrink tubing, and insulation tape

Step-by-step Guide To Assembling The Charger

Once you have all the necessary tools and materials, you can proceed with assembling the 36-volt battery charger by following these steps:

- Set up a well-ventilated workspace with ample lighting.

- Connect the 36-volt transformer and bridge rectifier according to the wiring diagram provided by the manufacturer.

- Solder the necessary components onto a perforated board, ensuring a secure and tidy connections.

- Use a multimeter to verify the correct voltage output and polarity.

- Assemble the components inside the chosen enclosure, ensuring adequate ventilation and heat dissipation.

- Connect the DC jack and test the charger with a 36-volt battery to ensure proper functionality.

Wiring Diagrams And Circuit Design

Understanding the wiring diagrams and circuit design is crucial for ensuring the proper functioning of the 36-volt battery charger. It’s recommended to refer to the manufacturer’s specifications for the transformer, bridge rectifier, and other components to create a reliable and safe charging system.

Testing Your Diy Battery Charger

Before fully utilizing your 36-volt battery charger, it’s crucial to conduct thorough testing to ensure it operates effectively. Proper testing will confirm that your charger can handle the specified voltage and current requirements, providing optimal charging performance for your batteries. Here’s how to test your DIY battery charger to ensure everything is in perfect working order:

Setting Up A Controlled Environment For Testing

To begin testing your DIY battery charger, it’s important to create a controlled environment to ensure accurate results. Find a well-ventilated area with a stable temperature and minimal interference to avoid any external factors influencing the testing process. Maintaining a controlled environment is key to obtaining reliable testing data.

Using Multimeters To Track Voltage And Current

Utilize multimeters to accurately measure the voltage and current output of your DIY battery charger. By monitoring these parameters, you can ensure that the charger is delivering the correct levels of power to your battery pack. Tracking these metrics will help identify any potential issues and confirm that the charger is operating within the specified parameters.

Adjusting Settings For Optimal Charging Performance

When testing the battery charger, make sure to adjust its settings to achieve optimal charging performance. Fine-tune the charging voltage and current as per the specifications of your battery pack. By optimizing the settings, you can ensure that the battery receives the ideal charging conditions, ultimately extending its lifespan and maximizing its performance.

Troubleshooting Common Issues

Common Assembly Mistakes And How To Avoid Them

When building a homemade 36V battery charger, it’s crucial to be mindful of common assembly mistakes that could impact its functionality. Some frequent errors include incorrect wiring connections, inadequate insulation, and mismatched voltage ratings. To avoid these issues, it’s essential to carefully follow the charger’s schematic diagram, double-check all connections, use proper insulation materials, and ensure that all components are compatible with the 36V system.

Tips For Rectifying Charging Malfunctions

Experiencing malfunctions in the charging process can be frustrating, but there are several troubleshooting tips that can help rectify common issues. If the charger fails to initiate the charging process, start by checking the power source and ensuring that all connections are secure. Additionally, inspect the battery for any signs of damage or corrosion, and consider measuring the voltage output from the charger to diagnose potential issues. In the event of a slow charging rate, verify that the charging current is set to the appropriate level and examine the battery’s condition for any signs of degradation or malfunction.

Maintaining Your Homemade 36v Battery Charger

Regular maintenance is crucial for preserving the functionality and longevity of your homemade 36V battery charger. Establish a routine for inspecting the charger’s components, including the wiring, connectors, and insulation, to identify any signs of wear or damage. Clean the charger and its surroundings to prevent dust accumulation and ensure proper ventilation. Additionally, periodically test the charging performance and voltage output to verify that the charger is functioning optimally. By staying proactive with maintenance, you can extend the lifespan of your 36V battery charger and minimize the risk of potential malfunctions.

Frequently Asked Questions On How To Make A 36 Volt Battery Charger

How Can I Make A 36 Volt Battery Charger At Home?

To make a 36 volt battery charger at home, you will need a transformer, diodes, capacitors, and a voltage regulator. Follow the wiring diagram and instructions carefully to ensure safety and effectiveness of the charger.

What Safety Precautions Should I Consider When Making A Battery Charger?

When making a battery charger, ensure proper insulation of wires and components, use gloves and safety goggles, work in a well-ventilated area, and double-check the wiring before connecting to a power source. Safety should always be a top priority in DIY electrical projects.

What Are The Advantages Of Making Your Own Battery Charger?

Making your own battery charger allows customization for specific voltage requirements, saves money compared to buying a pre-made charger, and provides a valuable learning experience in electronics and DIY projects. It can also be a rewarding and practical skill to have.

Conclusion

Making a 36-volt battery charger is a rewarding DIY project. With the right materials and a step-by-step guide, you can create a charger to meet your specific needs. This process offers cost savings and the satisfaction of building your own electrical device.

By following these instructions, you can enjoy a fully functional and customized battery charger.